Click to view our Accessibility Statement or contact us with accessibility-related questions

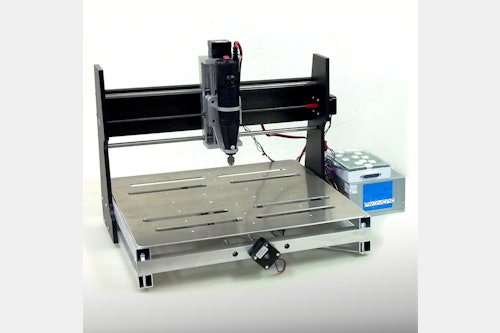

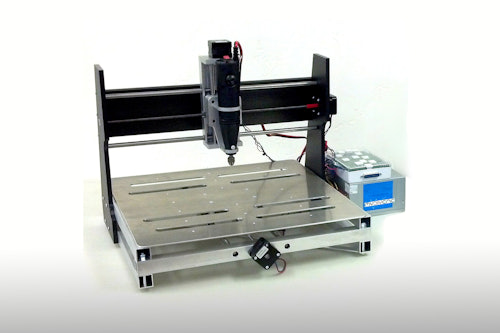

Bigfoot Desktop CNC Machine

Bigfoot Desktop CNC Machine

bookmark_border

Where's the price?

To negotiate the best possible price for our customers, we agree to hide prices prior to logging in.

81 requests

search

close

Sort by: Newest

keyboard_arrow_downjonathan.clawson

1

Apr 9, 2014

What type of materials can this machne and approximately how thick. I'd like to use this on copper brass and very mild steel materials.

Brindley

4

Apr 7, 2014

Is the laser upgrade on this capable of etching/cutting glass? Could not find the information on their website. Wish their website had more images/videos of projects that were created with this device. Looks very exciting, but more interested in it for use with laser.

gumballguy

20

Apr 8, 2014

BrindleyI'm similarly interested for the laser as well as the router. Wont have time to think about this before being overseas. Hope it comes back again to massdrop.

mydiycnc

9

mydiycnc

Apr 8, 2014

BrindleyNot glass I’m afraid as the wavelength of laser light used passes clean through glass. You can coat/paint the glass and use the laser to etch away the paint revealing glass underneath. We’re working on a gallery of examples from both in-house and from our customers to show the capabilities of the machine. Now that we have a new hosting company for our website that is now possible.

gumballguy

20

Apr 5, 2014

Would love to get one. Is the shipping amount definately correct ($190 to AU)?

The problem is that if I commit at the lowest price, it'll cost $1194AUD.

But if another $50 can be knocked off somewhere, it'll only cost $988 AUD

That's a massive $206AUD difference.

(The reason is that Australian customs charges us 15.5% more on the item value and 10% more on the post value for items where cost including post is > $1000AUD)

Edit: I was looking into it and the taxes may not trigger unless the item itself is >$1000AUD *excluding* post. Guess I should call them to be certain, I dont want a bill for another $206.

That's a massive $206AUD difference.

(The reason is that Australian customs charges us 15.5% more on the item value and 10% more on the post value for items where cost including post is > $1000AUD)

Edit: I was looking into it and the taxes may not trigger unless the item itself is >$1000AUD *excluding* post. Guess I should call them to be certain, I dont want a bill for another $206.

chris_lucero

0

Apr 5, 2014

What is the controller and software I can use? I have Solidworks and HSMworks, CAD/CAM package and would like to know how I can work with this as far as post processing editing to actually create what I see on the screen. Honestly the assembly isn't any big deal but dealing with the software side can be a nightmare.

Appreciate the help, new to massdrop, in case this info is listed somewhere.

mydiycnc

9

mydiycnc

Apr 8, 2014

chris_luceroThe MyDIYCNC Desktop CNC Machines can be used with KCam, EMC2 or Mach3 using it’s native parallel port. Add the USB Solution and it comes with FabCAM CNC software. All of these apps process GCode on the machine, so an important aspect is to determine where you get your GCode. The best solutions use already-familiar CAD apps (such as SketchUp, Solidworks and HSMworks) to create your design and export to GCode (with plugin), DXF or STL format.

Those files (DXF & STL) can be read by MeshCAM which is a tool you would use to determine your toolpaths to mill the piece, and then export those instructions as GCode. MeshCAM in particular has a FabCAM output option which produces clean, standard GCode which FabCAM requires. The advantage to using a product like MeshCAM is that it allows control over the milling process as different toolpaths will give different milled results for the same model. The cool think about MeshCAM is that with it’s wizards it is by far the easiest way to get from CAD to GCode and milling. With MeshCAM and FabCAM the production processes becomes very simple.

Those files (DXF & STL) can be read by MeshCAM which is a tool you would use to determine your toolpaths to mill the piece, and then export those instructions as GCode. MeshCAM in particular has a FabCAM output option which produces clean, standard GCode which FabCAM requires. The advantage to using a product like MeshCAM is that it allows control over the milling process as different toolpaths will give different milled results for the same model. The cool think about MeshCAM is that with it’s wizards it is by far the easiest way to get from CAD to GCode and milling. With MeshCAM and FabCAM the production processes becomes very simple.

dmcewan

2

Apr 11, 2014

mydiycncIs there a method for sending gcode directly without MeshCAM or FabCAM? Support for Linux is the only thing holding me back and they both seem to be CLOSED SOURCE which seems a tad "retro" these days.

Is it possible to use any of the open source tools e.g. the one listed here? http://replicat.org/generators

EDIT: Just to clarify, I understand you don't need MeshCAM and that any standard g-code generator should work; but how do you upload the g-code without FabCAM on an modern computer which has no parallel port?

EDIT: Just to clarify, I understand you don't need MeshCAM and that any standard g-code generator should work; but how do you upload the g-code without FabCAM on an modern computer which has no parallel port?

Brindley

4

Apr 4, 2014

How difficult is it to assemble this kit? Also, with the laser attachment, is that laser strong enough for glass etching?

mydiycnc

9

mydiycnc

Apr 8, 2014

BrindleyHere’s answer to #2. More to follow later:

The BigFoot comes with several pictorial step-by-step assembly instructions. Tech support is also provided with the purchase via website HelpDesk, e-mail or phone. You can see the assembly instructions here: http://www.mydiycnc.com/sites/default/files/MyDIYCNC%20Desktop%20CNC%20Machine%20Kit%20Assembly%20Instructions.pdf

No, the laser will not etch glass. For that you need a laser wavelength that is absorbed by glass so that the laser energy is transferred to the material in order to etch it. It will etch tinted acrylic however.

The BigFoot comes with several pictorial step-by-step assembly instructions. Tech support is also provided with the purchase via website HelpDesk, e-mail or phone. You can see the assembly instructions here: http://www.mydiycnc.com/sites/default/files/MyDIYCNC%20Desktop%20CNC%20Machine%20Kit%20Assembly%20Instructions.pdf

No, the laser will not etch glass. For that you need a laser wavelength that is absorbed by glass so that the laser energy is transferred to the material in order to etch it. It will etch tinted acrylic however.

mydiycnc

9

mydiycnc

Apr 8, 2014

DoormattYou should consider the following when deciding between the two.

Shapeoko 2 workspace is 11.8" x 11.8" x 1.96", compared to the BigFoot's 15" x 13" x 3.7". The Z axis (3.7") is particularly important as this is your clearance height for the piece of material you'll be milling.

The BigFoot moves the table/piece whereas the Shapeoko 2 moves the gantry over a stationary project - pros and cons to both, but typically the fixed gantry is stiffer and has less play which maintains precision and repeatability.

Shapeoko 2 uses an Arduino+ shield and GrBL for their electronics/software control. You should compare GrBL to FabCAM for useability.

BigFoot uses purpose-made machined billet aluminum for carriages. This was a design improvement over prior model's bolt-together parts to simplify assembly, add rigidity, eliminated complex alignment procedures and maintains precision and repeatability.

BigFoot uses a machined aluminum table incorporating threaded holes and slots for attaching your project material.

Shapeoko 2 workspace is 11.8" x 11.8" x 1.96", compared to the BigFoot's 15" x 13" x 3.7". The Z axis (3.7") is particularly important as this is your clearance height for the piece of material you'll be milling.

The BigFoot moves the table/piece whereas the Shapeoko 2 moves the gantry over a stationary project - pros and cons to both, but typically the fixed gantry is stiffer and has less play which maintains precision and repeatability.

Shapeoko 2 uses an Arduino+ shield and GrBL for their electronics/software control. You should compare GrBL to FabCAM for useability.

BigFoot uses purpose-made machined billet aluminum for carriages. This was a design improvement over prior model's bolt-together parts to simplify assembly, add rigidity, eliminated complex alignment procedures and maintains precision and repeatability.

BigFoot uses a machined aluminum table incorporating threaded holes and slots for attaching your project material.

Rambonobo

207

Apr 4, 2014

Erm... I have to stay away from Massdrop. This is ridiculously tempting.

Edit. By the way, there is no way you have 9.25m^3 of milling area. 0.381x0.330x0.094=0.0118m^3 unless I am missing something fairly fundamental.

Edit. By the way, there is no way you have 9.25m^3 of milling area. 0.381x0.330x0.094=0.0118m^3 unless I am missing something fairly fundamental.

AndrewLekashman

2368

Input Club

Apr 4, 2014

RambonoboOh snap! You're correct, I ran it through Wolfram Alpha to figure out the volume, and I think it made a cube with one of each of these as a side.

Here's a link to the Wolfram Alpha results, which has some pretty cool stats in it, like 2.1 times the volume of a soccer ball, or a mass of 26 pounds of water.

https://www.wolframalpha.com/input/?i=381+mm+x+330+mm+x+94+mm

Here's a link to the Wolfram Alpha results, which has some pretty cool stats in it, like 2.1 times the volume of a soccer ball, or a mass of 26 pounds of water.

https://www.wolframalpha.com/input/?i=381+mm+x+330+mm+x+94+mm

Recent Activity