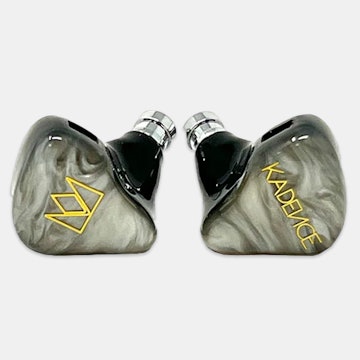

Ferrum Technology Estate 7-Inch Santoku Knife

American Craftsmanship, Universal Utility

Handcrafted in the Willamette Valley of Oregon, a quasi culinary graceland, the Estate 7-inch santoku is designed to make things easier in kitchen. Starting with the shape, its a wide-bellied santoku that excels in chopping vegetables and food prep. The blade weighs enough to breeze through veggies, fish, and poultry, but it’s not so heavy that the knife is difficult to wield. Made from commercial-grade American steel, it’s cut with dimples that help food slide off the edge. The handle has a wood-like appearance, but it’s made from polycarbonate for a better grip. Hold the knife at different angles and you’ll notice a slight shimmer in both the blade and handle. The bolster is tapered, too, which helps you get a better hold when using a pinch grip. Cut with Ferrum’s 16-degree “apple seed” edge, the blade offers long-lasting performance.

Note: This drop is limited to 50 units. Due to the sensitive nature of shipping knives internationally, we can only ship this knife to select countries. It is the responsibility of the buyer to know and comply with all importation regulations and local laws. Click here for additional information.

Specs

- Ferrum Technology

- Blade: Commercial-grade American steel

- Handle: Food-safe polycarbonate

- 16º edge

- Full-tang construction

- Tapered bolster

- Blade length: 7 in (17.8 cm)

- Handle length: 5.3 in (13.5 cm)

- Overall length: 12.3 in (31.2 cm)

- Weight: 10.3 oz (292 g)

Shipping

Estimated ship date is May 7, 2018 PT.

Payment will be collected at checkout. After this product run ends, orders will be submitted to the vendor up front, making all orders final.