Click to view our Accessibility Statement or contact us with accessibility-related questions

PRODUCTS YOU MAY LIKE

Trending Posts in Mechanical Keyboards

lwthunder

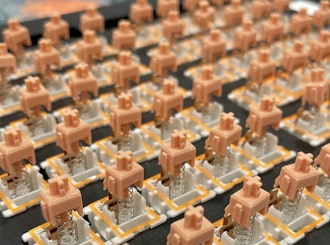

Drop CTRL V2 Mechanical Keyboard PCBA

If I want some hot-swap socket for replacement, where I can buy to ensure it fits this PCBA?

Apr 17, 2024

ThereminGoatMK

Do I Need to Lube My Keyboard Switches?

Figure 1: Sometime around here is a good time to ask that question... If you’re new to the mechanical keyboard hobby, I have no doubt that planning your first keyboard build is a bit of a daunting task. To be entirely honest with you, it’s only a tiny bit less daunting for your second or even third keyboard builds should you stay around a little while longer. You’ve got the keyboard itself to worry about, stabilizers, keycaps, and even switches on top of all of the intangible marks you want your dream keyboard to hit. Switches are especially daunting right out of the gate as there’s just so many options out there to pick from – each with their own unique specifications, manufacturers, and more. Yet, in spite of all of these differences between switches, time and time again I find people always asking about lubing switches as one of their chief concerns when it comes to picking some up. With countless numbers of content creators talking about lubing switches, its no...

Apr 17, 2024

TiKiToPia

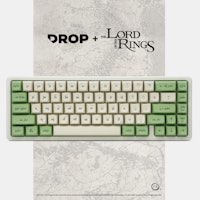

Keyboard & Drink

Playful set

This set goes better for keyboards meant for personal-casual setups as opposed to office-work environments.

Apr 14, 2024

Keyboy

help Momoka zoo 65

What is the diameter and length of the screws for the momoka zoo 65

Apr 14, 2024

jtgas23

ALT V2 not detected with Drop Keyboard Configurator

Hi, This is my first non-mac keyboard. I was under the impression that this would work out of box with with mac desktop however I am having issues getting the ALT V2 detected with the keyboard configurator software. The keyboard is plugged in and powered on. Apologies if this is very basic or if I have used incorrect language describing my issue, I don't have experience with this. Thank you

Apr 13, 2024

Since I cannot speak english I asked a friend to help me write here. I wanted to clear up a few questions/confusions many were having.

It is true that the modeling is done with a 3D printer but only for the original form. I 3D print them myself but what a lot of people do not know is that the surface area of the 3D printed objects are not smooth.

The device I use to 3D print the original form is one of the most accurate printers which is on par with the quality I of work I pursue myself. (The 3D print setup roughly costs $200,000)

However, even this printer cannot print an object with a smooth surface.

What I do is, I cut and sand the printed cap myself to make the shape and quality I am satisfied with.

The manufacturing process of artisan keycaps are generally similar for every keycap.

Silicon is used to make the mold for each keycap design.

This is where things get difficult and many fail.

The silicon mold contracts ever so slightly. This does not affect the shape or quality but for keycaps the contraction makes it difficult to use on mx switches.

Considering the contraction, making adequate space is extremely difficult.

If too loose, the keycap can come off too easily. If too tight, the keycap/switch may crack.

For the 3 years of making artisan keycaps, this was the hardest part.

Every time I would make a keycap I would adjust the shape and size, ultimately to make the quality of keycaps I am confident to release.

Even making the same shape I did, environmental/seasonal changes affect the time for the resin to solidify in the silicon mold.

Also, depending on the shape of keycap, getting the right silicon mold is a process of trial and error.

You may want to look at other artisan keycaps, there are rarely any that has protruding parts like this current project.

The reason is, the silicon mold and/or resin has a higher chance to create air bubbles on protruding parts.

These air bubbles can create holes varying in size on the finished product.

Once we can have a form with no holes or bubbles I inspect and adjust each keycap extracted from the silicon mold to make sure it is on par to my level of quality.

Can other artisans make delicate and detailed projects? Yes but it is the difficult manufacturing process that sways others to make complicated shapes.

My job is a jeweler making complex forms. I have been in this industry for 14 years now, so naturally my first keycap was made of metal.

Also, the one helping me with the silicon molds has been making molds for over 20 years.

Despite years of experience we still have a hard time making molds from unique shapes that may cause air bubbles.

Honestly, comparing other simple shaped keycaps makes me sad.

It may not look like much, but the process itself is very challenging.

I want to answer as much as possible but the friend translating this for me may have a hard time. (Not at all its my pleasure ;) hehe)

I would like to talk with all of you and answer any confusions.

If you have any concerns or questions feel free to email me (girldc@naver.com) or contact me through other keyboard enthusiast communities (GH/reddit).

However, please use simple words and phrases so I can understand better.

Now everyone knows these aren't 3D printed even though if you have two eyes and some brain cells you could clearly see they are molded and not printed.

Why did you choose to make an SCV? Do you have plans to make other gamer-related keycaps?