Click to view our Accessibility Statement or contact us with accessibility-related questions

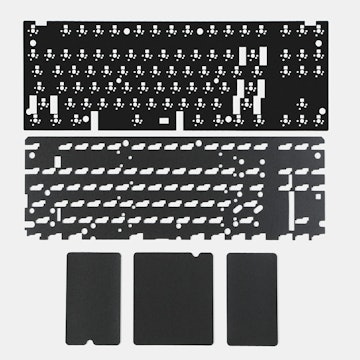

Haiku Kurouchi Tosa Knives

Haiku Kurouchi Tosa Knives

bookmark_border

Where's the price?

To negotiate the best possible price for our customers, we agree to hide prices prior to logging in.

428 requests

Product Description

The Japanese may very well be the premiere makers of kitchen knives across the world. These Haiku Kurouchi Tosa knives are crafted in the Tosa region of Southern Japan, known for its long tradition of knife forging and wild, unfurrowed landscape Read More

search

close

Sort by: Newest

keyboard_arrow_downmatt98030

93

Feb 5, 2019

I like these knives, I got two, a 5 inch and an 8 inch. They're nice and sharp and do a great job, only a couple minor problems. I have cut my finger twice on the squared off corner at the base of the blade nearest the grip. I actually took a file to knife and rounded that corner a bit. Also the handle pulled off one of the knives, it was easy enough to push it back on, but it seems like it should be on their more securely.

sockpuppy

451

Jul 25, 2018

This is a $50 knife with a made up $350 "MSRP" so you think the ripoff $170 pricing is a steal, aimed at people who have never seen a kurouchi knife before and are easily bamboozled by random Japanese words.

Perfect example of price anchoring and why it works.

Perfect example of price anchoring and why it works.

homeless

43

Jul 24, 2018

looks like it will rust in notime, if you forget to dry with towel after wash.

mrkaramba

12

Feb 3, 2019

teschiWhile Herder are told to be greatst German knives, they are not cheap, however they are only German knives which can compete with Japan blades

numonix

94

Mar 27, 2018

I wonder why options 1 and 8 are not available in the selection menu.

If option 1 where to be made available i would also purchase it.

KettleCrooked

15

Mar 18, 2018

I got my Santoku and have been using it for a while. It is truly a piece of artwork and handy. Obviously better than those I found in a supermarket (I won't tell you its name, sorry).

ScoobyWan

85

Feb 23, 2018

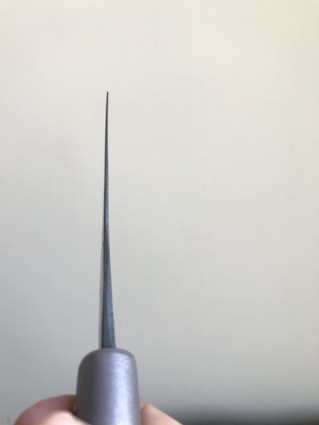

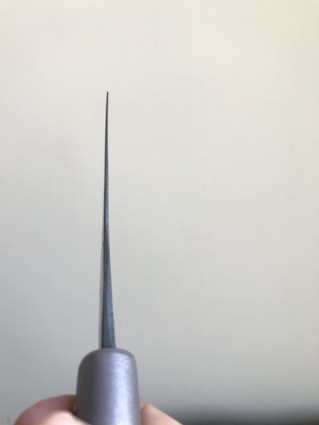

knives arrived a couple days ago and alt they are very good looking I am somewhat disappointed with the quality of the blades as they have a slight bend in them which is really frustrating on a knife of this price. I am including photos where you can see both the nakiri and the gyuto have a slight curve along the length of the blade.

myrna_brean

91

Sep 5, 2018

I have one, it is great. I have shopped i. The beverly hills store and online.

Kavik

5531

Sep 5, 2018

myrna_breanThat's funny, that looks like it might be the same knife I was talking about, and that looks just like my cutting board too lol

Unfortunately it's the wrong coast for me, but if I ever make it back out that way I'm definitely making time to stop in there 👍

Unfortunately it's the wrong coast for me, but if I ever make it back out that way I'm definitely making time to stop in there 👍

saumilkt

2

Feb 15, 2018

*psa* I am completely new to knives and know nothing.

What's so special about the atsu deba that makes it so much more expensive than the vast majority of the other knives?

What's so special about the atsu deba that makes it so much more expensive than the vast majority of the other knives?

Fuzz

396

Jul 27, 2018

Good points about the Deba,

I don't know so much about this series of videos though...they are not a great representation of Japanese cuisines and knife skills to say the least.

I don't know so much about this series of videos though...they are not a great representation of Japanese cuisines and knife skills to say the least.

greyworlder

77

Jul 27, 2018

FuzzHe is a pretty well-known chef who was trained up the traditional way in Japan, and tends to be lauded for his knife skills (though not with the deba specifically), so I think he's probably doing alright at least. You're free to disagree of course, but the man's abilities as a sushi chef are pretty well established by sources other than myself. As an anecdote though, I have actually met him, and what you see in the videos is certainly not all he's capable of. That really wasn't why I used it though. Honestly, it was just the first video that came to mind of a person handling a deba where the knife was extremely visible.

Showing 31 of 67

Recent Activity