Massdrop x Raleigh Denim Jones Slim

Handcrafted in North Carolina

To be, rather than to seem: It’s North Carolina’s state motto, and one adopted by local jeans maker Raleigh Denim. It stands for jeans made the old-school way—in small batches of about 300 pairs; slowly, with no automation, using hand-graded patterns and refurbished machinery from the glory days of denim in the Blue Ridge Mountains. It means learning from those who came before, like Cone Mills White Oak and Taylor Togs (America’s last Levi’s factory), and applying that knowledge to the fit and features denim lovers want today. It means, simply, that you get what they say you’re getting. Raleigh Denim: denim from Raleigh, unpretentious and made to last.

Long-Wearing Jeans in a Best-Selling Fit

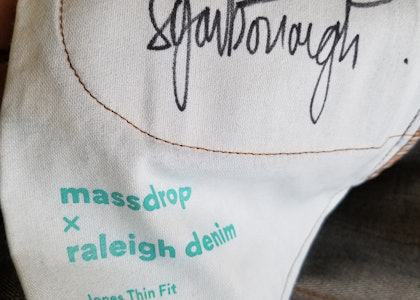

These jeans use 13-ounce rope-dyed indigo sanforized denim from Japan’s Kaihara Mills. One of the most requested fabric weights, it isn’t too difficult to break in, though it’ll still wear you a bit before you wear it. Based on community feedback, we worked with Raleigh to create a clean, traditional look, with a hidden selvage coin pocket and no mitered corners on the back pockets. The jeans are cut in the best-selling Jones fit—slim, straight, and classic—and feature Raleigh's signature red chain-stitch hem, sewn in the company's own workshop on heirloom machinery: a 1920s Union Special 43200G machine originally used to seal feed bags. Every back pocket takes about 20 minutes to put on (versus 11 seconds using more common automated processes). Finally, each pair is hand-signed by one of Raleigh's jeansmiths.

The Magic of Rope Dyeing

The rope-dyeing process involves repeatedly dipping a rope of cotton yarn into a series of indigo dye baths. Between dips, the yarn is exposed to the air and the absorbed indigo slowly oxidizes, turning the yarn blue. Because the yarn is never left in the bath long enough for the dye to penetrate to the core of the yarn, the outer circumference is dyed while the core remains white. With wash and wear, the denim will gradually shed layers of dye and slowly reveal the white core underneath. This makes for an extraordinary depth of color and a handmade feel that can’t be mass-produced.

About Raleigh Denim

Victor Lytvinenko and Sarah Yarborough started making denim in their Raleigh home in 2007, working together to teach themselves the craft. The couple made a pair of jeans a day using the three sewing machines in their living room—the first major investment in their new business—before seeking out informal apprenticeships with factory workers, patternmakers, and craftspeople throughout the state. Just over a decade later, the company has been featured in publications like The New York Times, Vogue, and Wallpaper; shown collections at New York Fashion Week; and stocked its jeans at high-end boutiques around the world. One of the few US companies to own its own factory, Raleigh Denim still uses the vintage sewing machines that first captured Victor and Sarah’s attention.

About Kaihara Mills

Founded in Japan’s Hiroshima Prefecture in 1893, Kaihara Mills originally specialized in handwoven, indigo-dyed kasuri: a fabric used to make kimonos. An innovator in the textile industry, it entered the world of denim in the 1970s when demand was very high and soon developed the country’s first rope-dyeing technique, which remains exclusive to them to this day. Today, Kaihara is still known for its unique in-house rope-dyeing techniques.

Behind the Scenes

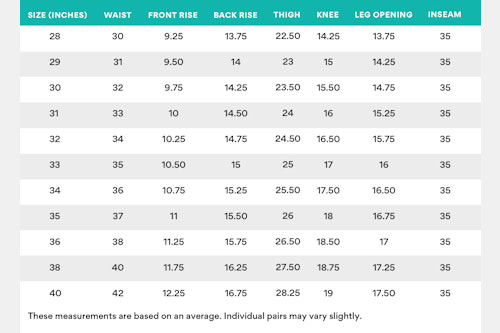

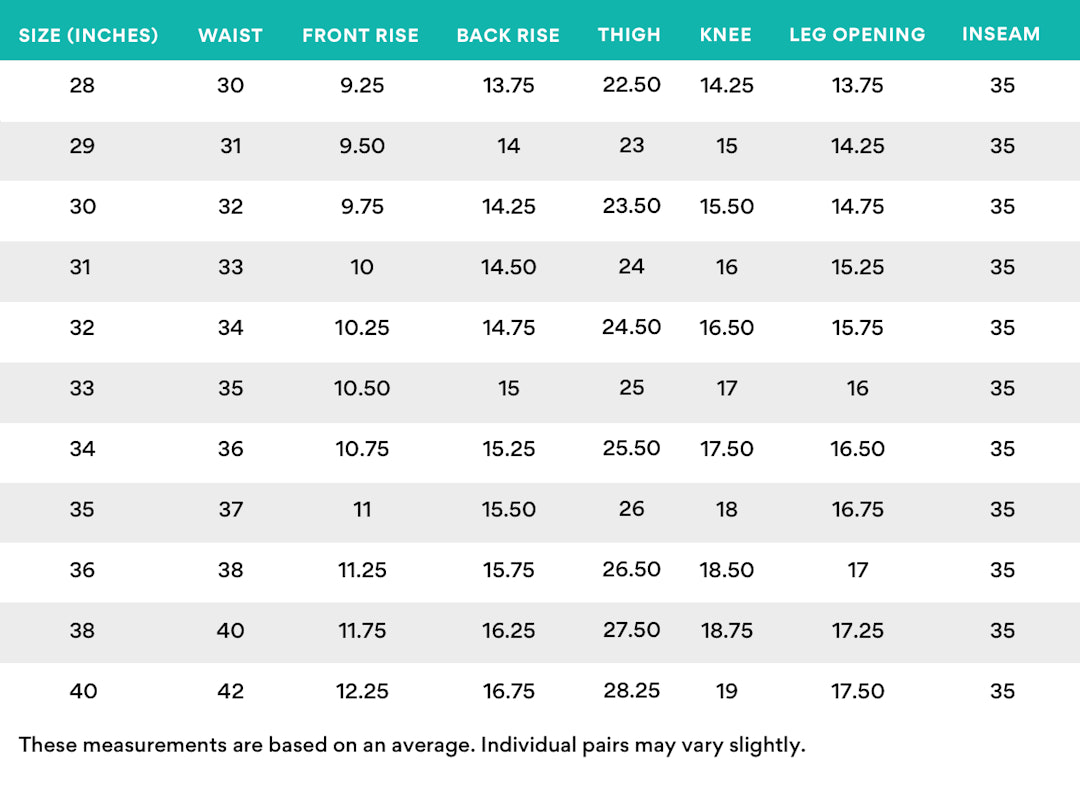

Sizing

When choosing your size, it’s important to follow the fit guide below. In general, these jeans fit true to size with a 15.5-inch leg opening, a 10.5-inch front rise, and a 35-inch inseam. We suggest taking the next size down if you’re between sizes. Expect the denim to stretch about 1 inch with wear. If your jeans start comfortably snug (or ever-so-slightly uncomfortably snug), they’ll stretch to be the next size up and a perfect fit.

Care

For the best break-in, Raleigh Denim recommends washing your denim for the first time after 3 to 6 months of regular wear. When it’s time, turn the jeans inside out and wash separately on a cold cycle. Hang or lay flat to dry. Due to the nature of the dyeing process, the indigo may bleed onto other fabrics.

Details

- Massdrop x Raleigh Denim

- 13 oz selvage denim from Kaihara Mills in Fukuyama, Japan

- 100% cotton

- Rope-dyed indigo

- Sanforized

- Button fly

- Hidden selvage coin pocket

- Selvage back belt loop

- Signature red chain-stitch hem sewn on Union Special 43200G machine

- Jones slim straight fit

- Hand-signed by Raleigh Founders, Sarah & Victor

- Made in Raleigh, North Carolina

Shipping

Estimated ship date is May 7, 2021 PT.

Payment will be collected at checkout. Cancellations are accepted up to 2 hours after checkout for in-stock items, or up until pre-order ships.