Click to view our Accessibility Statement or contact us with accessibility-related questions

Massdrop x Schwarz Perpetua EDC Folding Knife

Massdrop x Schwarz Perpetua EDC Folding Knife

bookmark_border

Where's the price?

To negotiate the best possible price for our customers, we agree to hide prices prior to logging in.

3.7K requests

·

Free Returns in USA

Product Description

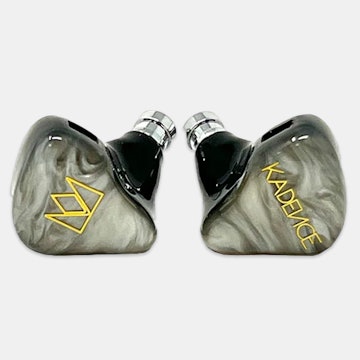

“Esto Perpetua,” or “let it be forever,” is the state motto of Idaho—and it’s where this heavy duty EDC knife gets its name. Designed by Idaho-based knifemaker TJ Schwarz and made by Millit Knives, this American-made folder is built to take on anything Read More

search

close

Sort by: Newest

keyboard_arrow_downDaghda

3

Sep 30, 2020

I would of liked the video more if they would ofshown them flipping and closing knife.

Cdoyle

400

Sep 6, 2020

On my perpetua the Blade edge hits the standoff... big ding in edge not too happy about that and had to disassemble and adjust the non shouldered standoff. Now it needs sharpened already...Smh. Also the thumb stud is hella sharp. Its a good knife for 100 bucks but QC is lacking just know that.

Laxnerd213

226

Dec 23, 2020

NotsurewhyibotherYeah I ordered one about a week and half ago when I first noticed the price had dropped again. I got a good one from a QC perspective, and I quite like the knife. Really like the shade of blue they used on the g10.

azraelsblade

93

Jul 22, 2020

Nice that new handle scale options are available, but Nitro-V should be run much harder than 58-59 HRc for optimal cutting performance. Hard pass.

14themoney

1395

Jul 3, 2020

Source: https://knifesteelnerds.com/2019/09/23/nitro-v-its-properties-and-how-to-heat-treat-it

Nitro-V looks very similar to AEB-L with a nitrogen and vanadium addition. The nitrogen addition, however, did not increase chromium in solution for enhanced corrosion resistance and the vanadium addition was insufficient for grain refinement according to simulation software. The nitrogen may itself increase the corrosion resistance somewhat relative to AEB-L. Nitro-V is capable of approaching 64 Rc when heat treated for maximum hardness, and can of course be heat treated for lower hardness as well depending on the desired properties. Nitro-V has a very fine microstructure and very good toughness when compared with other steels. Overall the properties of Nitro-V are expected to be similar to AEB-L with perhaps an improvement in corrosion resistance,

I am thrilled to see Drop post HRc values. Thank you, Jonas. But the values for this blade do not make it anything special or does it serve as a reason to consider purchase.

I am thrilled to see Drop post HRc values. Thank you, Jonas. But the values for this blade do not make it anything special or does it serve as a reason to consider purchase.

(Edited)

14themoney

1395

Mar 2, 2021

HoaxMugI do have one of those. I have not had it tested, but it has been impressive so far.

UncleMusket

166

Jun 11, 2020

I've tried every significant knife locking mechanism and the Axis lock is by far my favorite. There is simply nothing else that can do one hand flick open/closed as well as this mechanism can. This looks like a great knife. I hope you offer it in different blades closer to the BM Tanto and drop point styles and in more scale colors.

R_A_S

1

Aug 13, 2020

I was thinking the same thing... the blue is nice. Nicer than my gray scales. May be time to get a bottle of Rit dye...

stoutdog

305

Aug 13, 2020

R_A_SGreat idea! Why didn't I think of that. If you do it, attach a photo. I might do the same. Thanks Bro!

(Edited)

Fishhead77

2

Jun 2, 2020

I put my order in on May 27. Drop sent me a refund yesterday 6/1 stating, the item I ordered was back ordered and they didn’t know when they would be available. This was the “gray” version..

Reordering the Green version.

Anyone else have the same issue?

Fishhead77

2

Jun 20, 2020

Fishhead77I received one of the green models a couple weeks ago.

I like it, the action is smooth.

It feels very robust, Just hate that I couldn’t get the color I wanted.

(Edited)

Washington

1

May 26, 2020

Has the pocket clip been revised?

I returned the early one I purchased. The early versions were very “soft”, would bend very easy and not spring back. Would like to purchase another one.

ecoleman

766

Aug 14, 2020

WashingtonI do believe they changed the pocket clip, no longer plain bendy stainless.

TipsyMacScotchslurpen

379

May 15, 2020

I'd be really interested in a smaller version of this knife. I currently carry a Bnechmade mini-Griptilian that is at least 8 years old, now. It would be nice to have a second knife as a secondary or just-in-case piece. The mini is something like 6 3/4" open, and I find that to be the sweet spot for me in knife size.

Narq

912

Jul 31, 2020

I don't own this knife, but dimension-wise, it seems closer to the Bugout. Price-wise as well. That being so, it is to the Perpetua's detriment. The Bugout is superior in every way- with better steel, and a MUCH lighter and slimmer body.

Judging by the reviews, the slide lock is nowhere near as reliable as the Bugout's. There are many comments regarding poor QC on the Perpetua. Which is concerning. I can't imagine anyone spending $130 on this Drop collaboration, rather than the Benchmade (unless one already has a Bugout and is just out collecting things).

(Edited)

JAWVA

2

May 8, 2020

Been using mine more than a week now. Rock solid. Not a thing wrong with it. In fact fit, finish, sharpness, lock-up, deployment all are top notch.

Showing 29 of 350

Recent Activity