Click to view our Accessibility Statement or contact us with accessibility-related questions

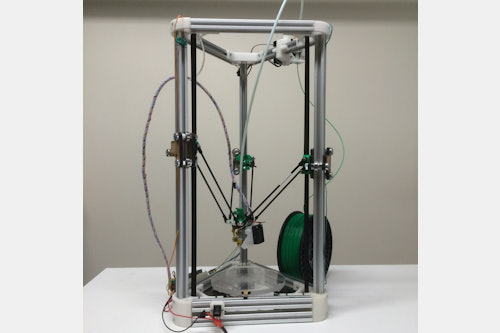

Mixshop Mini Kossel 3D Printer Kit

Mixshop Mini Kossel 3D Printer Kit

bookmark_border

Where's the price?

To negotiate the best possible price for our customers, we agree to hide prices prior to logging in.

468 requests

search

close

Sort by: Newest

keyboard_arrow_down

ricecooker7654

9

May 2, 2014

So I'm not sure how everyone else's experience with this kit are going, but I'm becoming more and more disappointed over the the wait and the money spent on this kit.

Although I knew their online instructions were minimal, it seems like alot of the kit was put together without much thought.

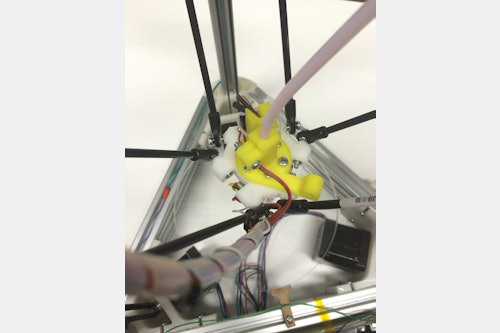

Several printed parts show warping, the lasercut parts are cut from a type of particle board which means poor strength on some of the thinner parts, and alot of the hardware doesn't seem to be sized appropriately (see picture. The arm should have full range of motion but it's blocked by the bolt). I realize the hardware issue is a issue fixed by a trip to the hardware store, but when I bought the kit I was assuming things like this wouldn't be an issue.

The condition the extruded beams were in was enough to make wonder what I was getting into. Most of them were already dirty and scuffed. But more importantly they were cut unequally.

Here's some of the pictures

http://imgur.com/a/6LVsu

I'm still going to try and make due with what I have available, but overall I'm none too impressed by this kit.

-drew

Although I knew their online instructions were minimal, it seems like alot of the kit was put together without much thought.

Several printed parts show warping, the lasercut parts are cut from a type of particle board which means poor strength on some of the thinner parts, and alot of the hardware doesn't seem to be sized appropriately (see picture. The arm should have full range of motion but it's blocked by the bolt). I realize the hardware issue is a issue fixed by a trip to the hardware store, but when I bought the kit I was assuming things like this wouldn't be an issue.

The condition the extruded beams were in was enough to make wonder what I was getting into. Most of them were already dirty and scuffed. But more importantly they were cut unequally.

Here's some of the pictures

http://imgur.com/a/6LVsu

I'm still going to try and make due with what I have available, but overall I'm none too impressed by this kit.

-drew

copterdriver

4

May 8, 2014

This is a link to the original builders manual: http://reprap.org/wiki/Kossel

If you go by the Mixshop manual you will be shown only part of the assembly. The obvious parts, and they are missing a lot of angles in the photography that would help figure out orientation of parts for assembly. Nowhere does it mention any of the wiring components or hot end electronics other than endstops/microswitches. A picture of the wiring diagram is included but the hot end heater and thermistor assembly is never mentioned.

It's not a big deal as long as you don't mind wasting a lot of time trial fitting parts and scouring the internet for solutions. I have the time, a lot of people don't.

If you go by the Mixshop manual you will be shown only part of the assembly. The obvious parts, and they are missing a lot of angles in the photography that would help figure out orientation of parts for assembly. Nowhere does it mention any of the wiring components or hot end electronics other than endstops/microswitches. A picture of the wiring diagram is included but the hot end heater and thermistor assembly is never mentioned.

It's not a big deal as long as you don't mind wasting a lot of time trial fitting parts and scouring the internet for solutions. I have the time, a lot of people don't.

copterdriver

4

May 8, 2014

The wooden parts will warp with changes in humidity unless painted. The build manual doesn't show the second wooden part in the assembly. There is no large screw supplied that will go thru the board and long enough to put a nut and washer on to attach it to the carriage. Two tiny screws and nuts, and a screw too short are all that attach the plastic to wood.

I replaced the axle bolts with a socket head cap screw that is 28mm long and assembled it like the "manual." The weight difference is considerable without all those nuts, long bolt, washers and the extra board. I think I can make this work temporarily.

I found this wheel assembly and will probably print something similar when I get the printer working. Some of the cheap bearings supplied are really loose and some preload would help. The tapered wheels I can make myself.

http://www.builda3dprinter.eu/shop/kossel-kit/rails-to-wheels-conversion-kit/

The magnetic arms will not make that much difference unless the carriages are running without play on the upright beams. The Traxxus ends are pretty tight and could probably be tightened more with the right socket, a vise and a hammer. Light and tight is the key for better precision and less wear on the machine.

Regardless, it's a fun process for me. Just wish some effort was put into documentation of the assembly of a few key things and attention to the rails being protected and clean before shipping. I live on the East Coast so my package was tossed around by UPS many times before it got here. Putting "Fragile" on a package just makes them throw it harder when loading... been there, seen that.

I replaced the axle bolts with a socket head cap screw that is 28mm long and assembled it like the "manual." The weight difference is considerable without all those nuts, long bolt, washers and the extra board. I think I can make this work temporarily.

I found this wheel assembly and will probably print something similar when I get the printer working. Some of the cheap bearings supplied are really loose and some preload would help. The tapered wheels I can make myself.

http://www.builda3dprinter.eu/shop/kossel-kit/rails-to-wheels-conversion-kit/

The magnetic arms will not make that much difference unless the carriages are running without play on the upright beams. The Traxxus ends are pretty tight and could probably be tightened more with the right socket, a vise and a hammer. Light and tight is the key for better precision and less wear on the machine.

Regardless, it's a fun process for me. Just wish some effort was put into documentation of the assembly of a few key things and attention to the rails being protected and clean before shipping. I live on the East Coast so my package was tossed around by UPS many times before it got here. Putting "Fragile" on a package just makes them throw it harder when loading... been there, seen that.

nelson

5275

Apr 23, 2014

Hey everyone,

Happy to report that all the orders from the drop have been shipped out!

Thanks again for the support guys, and please feel free to share your experience of the Mixshop Mini Kossel 3D Printer Kit with the rest of the group afterwards.

If there’s anything else we can do to make your Massdrop experience better, feel free to email us at support@massdrop.com.

nelson

5275

Apr 22, 2014

Hey everyone,

Great news! Our order of Mixshop Mini Kossel 3D Printer Kit has arrived in our warehouse earlier today.

Our warehouse staff are working on breaking down the bulk shipment and repackage them into individual orders before shipping them out to everyone. We are aiming to have everything shipped out within the next 24 hours.

Once your order is shipped out, you’ll be getting a notification email from us with shipment tracking information.

Cheers!

nelson

5275

Apr 13, 2014

Hey everyone,

We have just been informed that our order of the Kossel 3D Printer Kit has been shipped out by Mixshop.

We have already alerted our warehouse staff about this shipment, so we should be able to process the bulk shipment upon arrival, and repackage them into individual orders before shipping them out to everyone very quickly.

We are expecting to have these out to everyone within 24 hours after the shipment arrives.

Since Mixshop is a vendor that is located in Canada, Canadian orders are being shipped out to the customers directly from Mixshop. We have updated all the Canadian orders accordingly with the tracking information.

Cheers!

nelson

5275

Apr 7, 2014

Hey guys,

We just received an update from Mixshop confirming shipment of the order in 2 days.

Since Mixshop is based in Canada, they will be helping us shipping Canadian orders directly from their facility. We will be handling shipments for domestic orders as well as orders from rest of the world.

As long as Mixshop ships us the order by the promised schedule, we should be able to have the orders shipped out to everyone before end of next week.

Thanks!

Nelson

koolatron

6

Apr 2, 2014

It’s been three weeks since the last update — does Massdrop have these on hand yet?

dddddeeef

0

Mar 22, 2014

what's that crazy discription! Gutenberg isn't the first one who have made the printing press,... It was first made in Koryo Dynasty(which is now Korea), two century faster than Gutenberg;;

Showing 16 of 31

Recent Activity