Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 59 conversations about:

punchy_lab

15

Jan 12, 2019

bookmark_border

Hello everyone. I’m the founder of Punchy Studio. When I bought my first DIY mechanical keyboard in 2013, I fell in love with this baby. In the next few years, I joined every buying group I found and bought every keyboard I liked. While enjoying the pleasure that these pieces of art brought me, I had a great deal of respect for the manufacturers, and their meticulous attitude and spirit of excellence also affects my life, work and study. But later I also found several problems: while mass-produced RGB keyboards flooded the market, DIY users were still struggling for the lights; while Bluetooth became standard, we had no choice but to comfort ourselves with “metal housing affects Bluetooth”; upper frame fastening, base frame fastening, semi-steel housing, PC positioning plate, carbon fiber positioning plate… none of these attempts could give us a feeling of finger massage. The year 2018 came and these regrets lingered in my mind.

At the beginning of 2018, I made up my mind to live my life with no regrets and set up the Punchy studio, determined to make a full-featured, industry-leading, stable and comfortable product to fill the market gap of customized DIY keyboards. However, my intuition and working experience in the manufacturing industry told me that things would not be that easy. Later I found that it had been pretty much the case. I kissed goodbye to all my holidays and free time and put a lot of energy into product design, packaging, and many other things. I used all my resources to look for a manufacturer that met my standards.

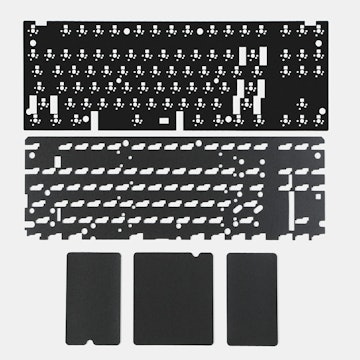

After confirming the product positioning and the general plan in March, we began to look for a high-end housing manufacturer. After consulting and visiting no less than ten factories, we managed to have the prototype sample produced by the end of April, mainly to test if the aluminum alloy processing and anode treatment meets our requirements. In the next 3 months, we made a total of five prototypes: the first model modified the overall height for more comfortable and practical use without hand support; the second model modified the internal battery compartment; the third model continued to modify the battery compartment for large-capacity battery and symmetry of appearance; the fourth model modified thickness of the frame so that the keyboard can be put into a briefcase; the fifth model modified the thickness of positioning plate. After collecting thousands of feedbacks from users and opinions of manufacturers, we changed the bearing pattern of the positioning plate to achieve more stable clicking and changed the thickness to meet the different requirements of users who prefer the linear switch or clicky switch. Finally, we made the prototype of the finished housing at the end of July. Next, we continued to look for a PCB supplier with a small order not even tenth of the large manufacturers’ MOQ. Doors were closed on us one by one, but we opened them again time after time. In the end, several companies agreed to cooperate with us. After determining appropriate plans for team product, we initiated a series of negotiations with the manufacturer and reached a costly contract of specially developed PCB for KB68. After that, we immediately produced more than ten sets of KB68 for inspection, problem-solving and various limit tests. In October, we received our first finished product.

As a newly established studio, we have no fame of well-known designers or representative works, but only our sincerity and high quality. In order to show our sincerity, we ordered 200 sets on our own funds just to relieve our customers of the anxiety of waiting. As to the quality of the keyboards, please have a look at the following data: In mid-December, 200 sets of KB68 were produced, and less than 120 sets met our standard and were accepted. 12 sets were slightly bumped during delivery with hardly visible damage of no more than 2mm x 2mm. Some other keyboards failed the checking due to some minor flaws, such as tiny scratches, anode stains no larger than a Cherry switch’s area, etc., because we want to provide the most cost-effective products to our customers and let everyone get to know Punchy as a brand of excellent quality and sincerity.

This is how KB68 was developed from concept to manufacture, from trial to finished product. Considering all the time, money and resources we put into it in nearly 300 days from February to December, the total cost and effort are beyond words. But when the keyboards are finished to my satisfaction, I can’t help but want to share with you.

We are proud to tell you that KB68 is a keyboard with stable transmission, complete functions, diverse usage and guaranteed quality. And so will be any other products from Punchy! This is Punchy’s promise. I want to thank you for your interest and support, with which we will steadily move forward and further improve our products!

Pejano

6

Jan 12, 2019

bookmark_border

punchy_labI appreciate the time you took to write this as well as the months of effort to bring this to market. This story obviously didn't translate onto the product page, which is why your average consumer would balk at the price tag. I actually think it's a beautifully constructed product, in my preferred layout (ISO would be perfect), with the right connectivity. However it's priced at a point that is aimed at enthusiasts, people with high disposable income, or people that just don't have a financial compass. Massdrop is a great platform for getting your product out on a global scale, but the product is really aimed at a niche market. In fact, when I saw the price I thought it was just Massdrop trying to rip people off again. So I appreciate you writing this and good luck with your business!

awkspace

36

Jan 12, 2019

bookmark_border

punchy_labI read through the whole thing but I still don't understand why a DIY kit without keycaps - or even switches - is $300. Many mechanical keyboard group buys are for products that have taken a lot of blood, sweat, and tears to manufacture, just like yours. But that fact alone isn't enough for me to justify $300 on something that will realistically take me at least another $100 to turn into a working product.

I can purchase the Massdrop CTRL keyboard for $150 if I choose a version without switches or keycaps included. Is wireless transmission alone really worth another $150?

Slayerage

185

Jan 15, 2019

bookmark_border

punchy_labIsn’t your team basically Team Revo, but with a new name?

sleepybrett

37

Jan 15, 2019

bookmark_border

awkspaceBluetooth module in single quantities generally maxes out at 15$ (most are far under)

OldCat

2500

Jan 16, 2019

bookmark_border

punchy_labUnfortunately massdrop is not the place to sell high-end boards. I think that’s what you intend this GB to. The target customer is just not right. The base who are willing to pay 300+ board is very limited. Geekhack is a better place, and then you will need to engage with the community a lot before they are willing to pour the money. Just my 0.02.