Click to view our Accessibility Statement or contact us with accessibility-related questions

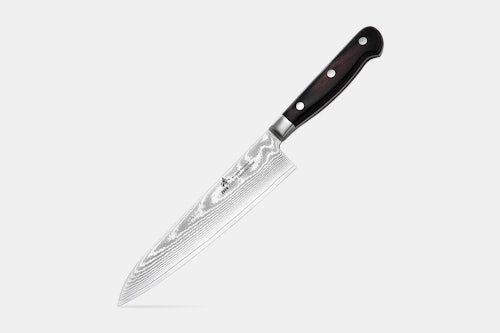

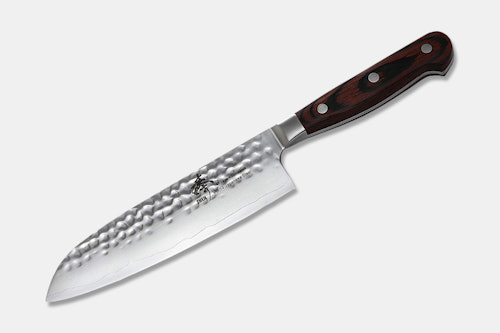

Zhen VG-10 Damascus Kitchen Knives

Zhen VG-10 Damascus Kitchen Knives

bookmark_border

Where's the price?

To negotiate the best possible price for our customers, we agree to hide prices prior to logging in.

342 requests

Product Description

The story of damascus steel dates back more than 2,000 years. Believed to have originated in India, it’s made by folding many layers of steel together in a unique pattern Read More

search

close

Sort by: Newest

keyboard_arrow_downOnefreeman

16

Oct 20, 2018

I‘ve ordered the 7” Veggie Cleaver and 5” Santoku; does anyone know if these knives come sharp!?

And, how sharp ?

...relatively 600grit, 1000, + ?

Thanks !

theMZA

41

Oct 15, 2018

anyone know the thickness on the butcher knife? is it thin like a chinese cleaver for veggie slicing or more for heavy duty stuff?

Jaggi

737

Oct 16, 2018

theMZAI think massdrop's attitude to product dimensions is something along the lines of "we could tell you, but then we'd have to kill you".

It may be this model: https://www.amazon.com/dp/B00E0EF7P0

In which case it's a thin (1.8mm) blade for veggies. But I can't guarantee it, I seem to remember in their 3-layer range they have otherwise identical looking cleavers in which the only difference is the thickness of the blade - a thin one for veggie prep and a thicker one (at least twice as thick) of the type that massdrop would probably use to dispose of your body if they ever accidently tell you the product dimensions.

It may be this model: https://www.amazon.com/dp/B00E0EF7P0

In which case it's a thin (1.8mm) blade for veggies. But I can't guarantee it, I seem to remember in their 3-layer range they have otherwise identical looking cleavers in which the only difference is the thickness of the blade - a thin one for veggie prep and a thicker one (at least twice as thick) of the type that massdrop would probably use to dispose of your body if they ever accidently tell you the product dimensions.

theMZA

41

Oct 16, 2018

JaggiYea, i think you're right. I even found it on the actual ZHEN website, and its the same dims as the one you sent a link of. Thanks!

https://www.zhenpremiumknife.com/collections/damascus-series/products/a7p-japanese-vg-10-67-layers-damascus-steel-light-slicer-chopping-chef-butcher-knife-6-5-inch-silver

theMZA

41

Aug 15, 2018

The 5 inch santoku option is not listed. Is it already sold out or is it missing by accident?

ajdasilva22

2

May 30, 2018

Hey Massdrop, are the other clever options gone. I only see the vegetable clever available now ?

NZMarkW

9

May 29, 2018

There is no option for the 7 inch vegetable cleaver when I go to join the drop???

MarcusK

25

May 26, 2018

so from my understanding, this is still considered san mai construction (3 layers)?

And 67 layers mean, vg10 core, and one 33 layered steel forged together on each side?

How does this differ in terms of edge retention when compared to the 3-layer forged?

Or is it purely aesthetics?

Krustyboomer

71

May 29, 2018

MarcusKThe extra layers are purely for looks. Only the inner core counts for the "edge" if it's san mai. The many layers in the outer steel account for the pattern (pattern welded). This could STILL be a solid pattern welded blade and not san mai. Still not sure how they folded to get 67 layers. Doesn't really add up, even if they did san mai.

ib1948

1

May 24, 2018

To Massdrop people...

Why is this drop or any kitchen knives drop, cannot be delivered to Israel ???

Showing 20 of 76

Recent Activity