Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 4 conversations about:

48thRonin2

117

Oct 24, 2018

bookmark_border

Not talking about jimping....

Talking about this:

Kavik

5531

Oct 25, 2018

bookmark_border

48thRonin2Unless you're hammering on the spine or whacking the knife into things, i can't imagine it's going to just break on it's own. (neither of which should be done with a folder anyway, as I'm sure you already know)

That example might be a little more angular than some, but all the corners on that one are radiused, none are sharp corners.

In theory, it seems to me that the force applied to the knife would travel through the blade in a triangular pattern between the stop pin, the pivot, and the contact point on the edge, right? I think in more cases than not that energy would be traveling under the cutout, if that description makes any sense, not up and over through the spine. But I guess that depends on exactly where the stop pin is located.

From a known designer and a respectable manufacturer though, I'm sure they've considered this. And I don't recall ever seeing anyone saying they broke a knife in the way you're talking about, have you?

Is it weaker than the same exact tall blade without a cutout? Sure, in theory.

But is it not the same (or maybe even a tiny bit stronger) as a knife with just a shorter overall blade height? Like, if you lopped off that whole top, would it still look to be of questionable strength to you?

I have one of those Minithiriums being delivered in a few days, and will be sure to post pics of the tear down to show how much steel is left around the pivot, and the angle to the stop pin, to see if you still think it's a concern on that one

48thRonin2

117

Oct 25, 2018

bookmark_border

KavikThank you for your reply!

On a previous drop, two users had their (solid) D2 blades snap between the pivot hole and the stop pin notch.

The responses on this forum were the usual apologist bs, "well, out of a drop of 200+ knives, ONLY two broke, so the probability is..." blah, blah, blah.

It seems to me that there are two types of purchasers in the world:

- Those with a lot of money who fill a safe full of "safe queens", and,

- Those who carry a knife and use it for whatever needs doing, and need to depend on it's reliability 100%. I am in the second group. As I said in a separate post, I use my knives (all of them) to slice, cut, and stick. I have no "safe queens".

Kavik

5531

Oct 25, 2018

bookmark_border

48thRonin2This is weird, we seem to have posted at just about the same time, and my other post disappeared. Sorry if it shows up a a duplicate later, but i'll roll it up into this response

I don't mind at all if we end up disagreeing, that's what makes conversations interesting lol

And it's all guesswork and theories anyway, no right or wrong till anything is proven.

But the point i was trying to get to is whether or not that's really as weak of a point as you think?

I remember the ones you're talking about having broke, but in those cases it was too thin of a ring of steel left around the pivot pin, that had been further milled out for a bearing cutout....definitely not great, but not sure it relates to this scenario

What I was trying to say is that I don't think much force from the edge would really even be transferred up and over that hole based on the geometry between the pivot pin and the stop pin.

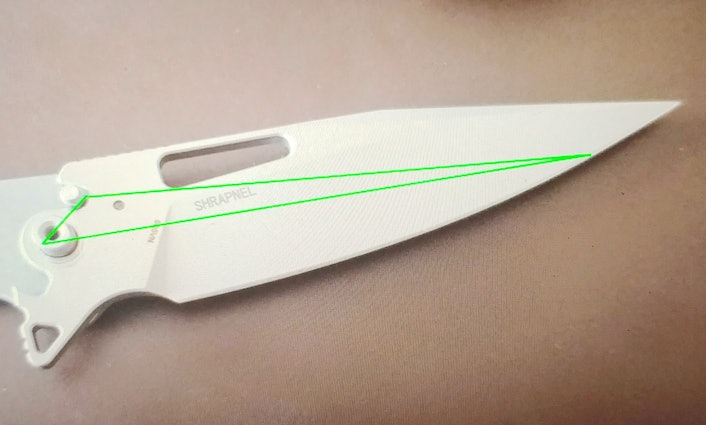

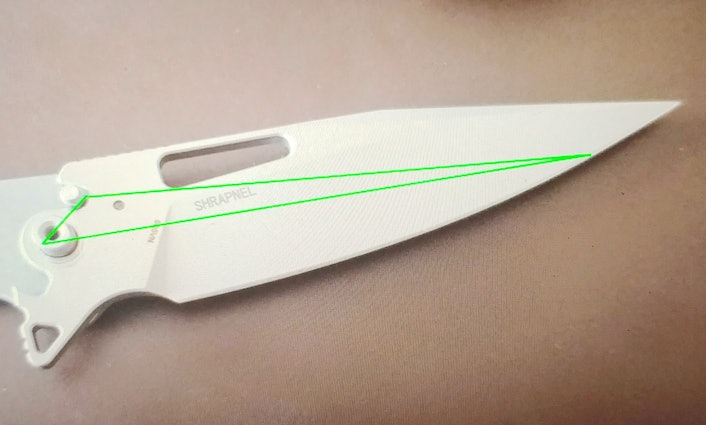

For example, with this knife i have on hand :

48thRonin2

117

Oct 25, 2018

bookmark_border

KavikAgree with everything that you bring up, geometry, force vectors and how much blade material separates the cut out from the pivot hole and stop pin notch will determine whether or not it will become an issue.

Another thing is whether or not the blade is cast (as in powdered steels) or drop forged with the cutout already formed or if the cutout is literally cut out of the blade - casting or drop forging being preferred before final tempering, physically removing material from bar stock with a plasma cutter or mechanical grinder / cutter can set up some issues for the final temper. (i.e., removing material that way may make the area around it more brittle if the blade gets too hot).

Good to have an intelligent conversation on here. (I still comment on "mall ninjas" in the "tactical" blades discussion!)

Kavik

5531

Oct 26, 2018

bookmark_border

48thRonin2Yeah, always enjoy a good, educational discussion 👍

I didn't get into steel types or manufacturing methods since we were talking about a general design feature, not a specific knife, but those are all excellent points as well.

Along with steel type your also want to consider final heat treat, whether the steel is going to be super hard and brittle, or a little softer and more forgiving... Whether it will bend or crack, and result in just a ruined knife, or a catastrophic failure that potentially puts the user at risk of injury

Side note : I wonder if a cut out from bar stock wouldn't be an issue if for with a water jet and before final temper?

God, i want a CNC and a waterjet sooo bad lol

48thRonin2

117

Oct 26, 2018

bookmark_border

KavikHey, maybe if you're good, Santa will bring you a CNC machine and a water jet cutter, along with a lifetime of Hitachi tool steel bar stock... LOL!

Make you an offer... you make them, ship them to me, and I'll "test" them...

Kavik

5531

Oct 26, 2018

bookmark_border

48thRonin2Lol i wish. First I need "Santa" to bring me a house, with a bit of land, so that i have room first to build a wood shop, then the machine shop would come after that...

Related Posts

aryomario

how can i get partnered?

Quick question I'm a tech toker does anyone know how I can get partnered by drop?

Mar 19, 2021

ggctech

Hey drop can you check out my tiktok it is ggctech i review stuff i was wondering if you can send something over that i can review or maybe follow i would love reviewing your products sounds interesting.

Thanks

Mar 18, 2021

jottoh12

What has happened to MassDrop?

I have been gone about two years and return to find a completely a different shopping experience. Even though Spring is upon us...I can count ALL the outdoor items on less than my 10 fingers. Is this the norm now from Drop? Thanks

Mar 16, 2021

TheRealGYK

Watching for watches

Where have all the watches gone? There are only 6 for sale (at the time of writing).

Mar 10, 2021

Lepiero

X-mid 1p tent available for France

Hello, my question is very simple: when will the Dan Durston X-mid 1p tent be available for France? I know this must have already been discussed and I know I can order it via Amazon.com but it is not the easiest (and cheapest) way to get it. Please, make it available! Don't let me beg you! ;-) Hope to hear from you soon with good news. Pierre

Mar 9, 2021

LarsAF

I bought a Glycine GL0187 and got it about a week ago.

The dial in the picture of the Glycine GL0187 on drop.com is black. The dial on the one i received looks 2/3 faded greyish and the bottom more black. I know it's not, but the dial has the water damaged look. It's not nice and pretty anoying. Any comments?

Mar 8, 2021

Trending Posts in More Community Picks

Graham88

Completely surprised by the lack of blade diversity here on Drop...

I’ve been a collector of Blades since before my teens, and a retailer coming up on 15… or maybe 20 years. Drop has really been kind of an interesting experience for me, because I do occasionally get to see some unusual tech and sometimes EDC items that otherwise I might not have been aware of. And maybe it’s because I have a deep love of cutlery and bladed weapons, but I find myself trolling through the site looking at it what’s available; and it’s just it’s pretty much the same. And the bladed community here is just always confused me.. every single knife is about the same, they’re almost all drop points and although the handle materials change and brands change.. it’s really just the same knife over and over and over again... occasionally you’ll see a tanto or a slight variant; but rarely… and almost never a serrated blade. And I’m just deeply amazed at this diversion of serrated blades. And I’m just surprised there isn’t more of a request for diversity here.... and I...

Mar 12, 2020

JellyDPhoto

Can we get Sony E-Mount or other mirrorless camera options please..

Would be nice to see some Sony E mount full frame cameras on here. I currently shoot with a A99 and they killed the lense path for better or more option lenses and now is all E-Mount. 🤔

Jan 13, 2020

RayF

There Are Pandas, and Then There Are Pandas.

And this isn't either of them! The Pandas we're talking about here, are watches, not bears. And what got me thinking about them (again) was a link posted this morning by @cm.rook who pointed a few of us to the very attractive (and not terribly priced) Yema "Rallygraph" Panda which, in it's most traditional arrangement, looks like the one on the left, but can also be had in the version on the right: The model on the left is a true Panda, while the model on the right is called a reverse Panda. The reason for that distinction is clear--Panda bears, only come in the first arrangement. Now at this point, everyone should be thinking about the most well-know Panda, The Rolex Panda, which is actually a Daytona, and among Rolex Daytonas, the most famous of which is the Paul Newman Daytona, which was famous first, because it was Paul's, and second because it sold at auction for $17.8 million (US Dollars). The story of that auction is well-known so I'll only...

Nov 8, 2019